Hotline

0799-6796868

Location : Home > Products > Steel Skeleton Series

Location : Home > Products > Steel Skeleton Series

ST ANDARD CARRIED OUT

GB/T32439-2015

steel wire mesh reinforced polyethylene composite pipe for water supply.

SY/T6662.1-2012《Fnon-metal composite pipe for petroleum and natural gas industries》.

GJ/189- -2007 steel wire mesh skeleton plastic polyethylene composite pipe and pipe fttings.

Gross helically wound steel wires reinforced- polyethylene composite pipelines for water suppy.

product specifications:

| serial number | product specifications | Pressure Rating(MPa) |

| 1 | dn75 | 1.6MPa、3.5MPa |

| 2 | dn90 | 1.6MPa、3.5MPa |

| 3 | dn110 | 1.0MPa、1.6MPa、3.5MPa |

| 4 | dn160 | 1.0MPa、1.6MPa 、3.5MPa |

| 5 | dn200 | 1.0MPa、1.6MPa 、3.5MPa |

| 6 | dn250 | 1.0MPa、1.6MPa 、2.5MPa |

| 7 | dn315 | 1.0MPa、1.6MPa、2.0MPa |

| 8 | dn400 | 1.0MPa、1.6MPa |

| 9 | dn450 | 1.0MPa、1.6MPa |

| 10 | dn500 | 1.0MPa、1.6MPa |

| 11 | dn560 | 0.8MPa 、1.0MPa |

| 12 | dn630 | 0.8MPa、1.0MPa |

Product technology:

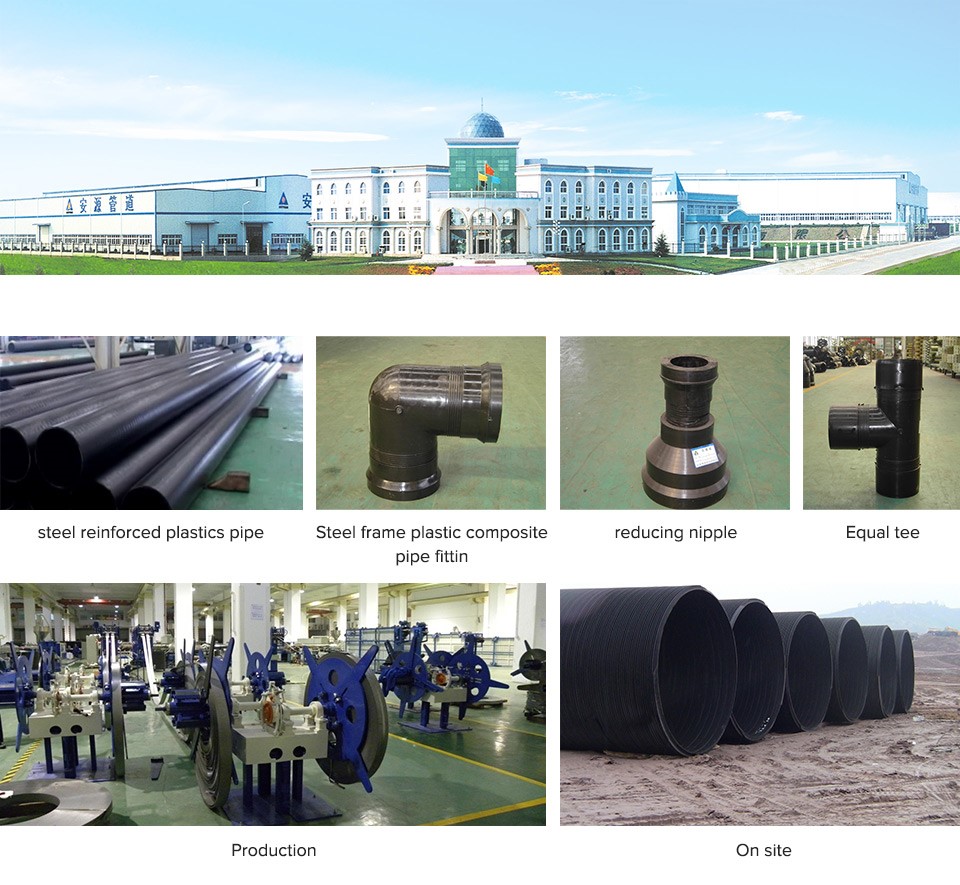

The company's steel skeleton plastic composite pipe and pipe have passed the technical standards of gas, industrial and water supply industries steel skeleton polyethylene plastic composite pipe and pipe fittings. After the industry standard has been upgraded, the steel skeleton plastic composite pipe and pipe fittings have experienced the development stage from low and medium pressure grades to low, medium and three pressure grades.

Production mode:

Steel skeleton of polyethylene plastic pipe is based on low carbon steel wire around the weld shape mesh steel skeleton reinforced phase, with good performance of high, medium density polyethylene as the matrix, extrusion and composite sync, on the production line continuous production of double-sided anticorrosion pressure pipeline, the pipeline corrosion, no scaling, smooth and low resistance, insulation and heat-resistant, no wax, wear resistance, creep resistance, flexibility, good stability, light installation is convenient wait for a characteristic, is widely used in petroleum, chemical, gas, water, mining and other industries.

The production method of steel skeleton polyethylene plastic composite pipe fittings is that the steel skeleton is heated in the mold and then molded by injection molding with high and medium density polyethylene with excellent properties.

Company production of the steel skeleton of polyethylene plastic pipe in today's world leading technology level, the product is relying on the Harbin industrial university to all the intellectual property and the steel framed hdpe pipe fitting, a national invention patents, 4 utility model patents, two patents in the United States, was identified as national key new product and included in the promotion, because of its advanced nature is known as a pipe manufacturing revolution.